The oil production industry is no stranger to challenges, from fluctuating market prices to the physical demands of extracting oil from the earth. Amid such complexity, choosing the right equipment can make a significant difference in operational efficiency and long-term profitability. One piece of equipment that continues to gain traction among industry professionals is the progressing cavity pump (PC pump).

This blog explores the true costs associated with PC pumps and why investing in them is a prudent decision for oil production industries. We’ll also examine how their design, functionality, and long-term benefits distinguish them from traditional pumps, making them a smart, cost-effective solution for oil producers.

What Are Progressive Cavity Pumps (PC Pumps)?

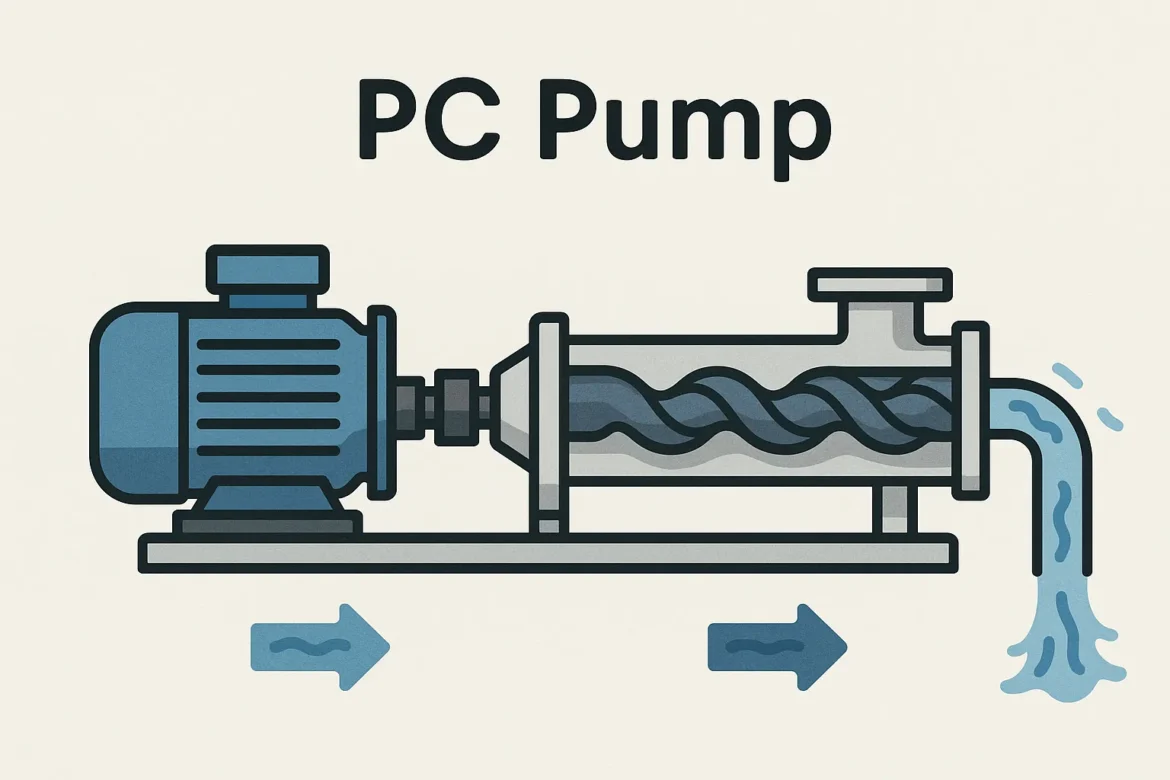

A progressing cavity pump, or PC pump, is a type of positive displacement pump designed to handle viscous, abrasive, or multiphase fluids. Its unique helical rotor-and-stator mechanism ensures a steady flow of liquids, regardless of viscosity. PC pumps have become prominent in the oil production industry due to their ability to handle complex applications, including crude oil extraction, dewatering, and chemical injections.

Unlike centrifugal pumps that rely on velocity and pressure, PC pumps deliver consistent flow and require less power, making them highly efficient for demanding operations.

The Costs Associated with PC Pumps

While progressing cavity pumps may have a slightly higher upfront cost compared to some conventional oil pump options, their long-term financial and operational benefits far outweigh the initial investment. Understanding the various types of costs associated with PC pumps is essential to appreciating their overall value.

-

Upfront Costs

Progressing cavity pumps require a larger investment at the point of purchase than basic centrifugal or reciprocating pumps. This is due to their sophisticated design, which includes precision-engineered rotors and stators made from high-quality materials. However, oil pump manufacturers often provide customization options to optimize PC pumps for specific applications, ensuring maximum efficiency right out of the gate.

While the upfront expense may seem significant, it should be considered a strategic outlay rather than a sunk cost.

-

Operational Savings

The efficiency of progressing cavity pumps translates into significant savings during operation. PC pumps reduce energy consumption by maintaining a consistent flow rate and requiring less energy to operate. Unlike conventional pumps that may experience performance drops, PC pumps excel in harsh environments, including handling high-viscosity fluids or fluids laden with solid particles.

This reliability ensures fewer disruptions in production, allowing operations to continue smoothly over extended periods without costly downtimes.

-

Lower Maintenance Costs

One of the standout benefits of PC pumps is their durability. Engineered to withstand abrasive materials, corrosive substances, and high pressures, these pumps are less prone to wear and tear compared to traditional alternatives. Most PC pumps have replaceable components, such as stator elastomers, which prolong the pump’s lifespan and simplify maintenance.

Maintaining a PC pump is also less labor-intensive. Because wear typically occurs in predictable patterns, inspections and component replacements can be planned well in advance, avoiding unexpected repair costs.

-

Increased Lifespan

The robust construction of PC pumps allows them to operate for years with proper care. High-quality materials combined with regular servicing can lead to extended lifecycle periods, further reducing the total cost of ownership compared to lower-quality alternatives that require frequent replacements.

-

Productivity Gains

Finally, the ability of progressing cavity pumps to deliver consistent, steady flows optimizes oil production processes. A more reliable pump reduces variability in extraction rates, improves production forecasts, and boosts profitability over time. This is an often-overlooked yet vital factor when calculating the total return on investment (ROI) of a PC pump.

Why Leading Oil Pump Manufacturers Recommend PC Pumps

The growing popularity of PC pumps in oil production is not coincidental. Many reputable oil pump manufacturers acknowledge their advantages and actively promote them as the ideal solution for challenging environments. Here’s why they’re highly recommended:

- Versatility: PC pumps are incredibly versatile, capable of dealing with a range of fluids and solids without compromising efficiency.

- Scalability: They can be scaled and customized to meet the specific needs of individual oilfields, ensuring tailored performance.

- Enhanced Safety: By reducing the likelihood of leaks and failures, PC pumps contribute to improved operational safety and environmental compliance.

- Alignment with Sustainability Goals: Their energy-efficient design contributes to more sustainable operations, helping companies align with environmental standards and goals.

The Hidden Costs of Neglecting PC Pumps

Choosing not to invest in progressing cavity pumps can result in hidden costs over time. Traditional pumps that require frequent repairs, replacements, or energy consumption can quickly erode profitability. Additionally, operational downtimes caused by pump failures may delay production schedules, leading to customer dissatisfaction and revenue losses.

Organizations that prioritize the short-term savings of cheaper alternatives often find themselves facing higher lifetime costs. For an industry as competitive and resource-intensive as oil production, such oversights can prove detrimental in the long run.

Final Thoughts

Investing in PC pumps is not just about upgrading equipment; it’s about adopting a smarter approach to oil production management. Their advanced functionality, energy efficiency, and lower maintenance requirements make them a cost-effective solution that can drive long-term profitability.

If you’re considering implementing PC pumps into your operations, consult reputable oil pump manufacturers to explore tailored solutions that meet your specific requirements. By analyzing upfront costs in the context of potential savings and ROI, you’ll find that a PC pump is more than an expense; it’s an investment in the success and sustainability of your business.